Issue 11 - Socio-economic impacts

The Kenyan Marine and Fisheries Research Institute has been commissioned to undertake a socio-economic study of the potential socio-economic impacts of biodegradable nets and ropes in Kenya. KMFRI is piloting biodegradable gillnets and ropes for seaweed farming and coral restoration. Beyond ensuring that the innovation does not harm, Catchgreen is interested in understanding how the project presents an opportunity to leverage or contribute to the transitions to a Blue Economy in its target countries. The study will investigate opportunities for direct job creation, possible boosting of existing net manufacturing industries, and whether the project has the potential to positively impact the welfare and living conditions of coastal communities in Kenya. The study aims to give context to artisanal fisheries and seaweed farmers and their visions and help the Catchgreen project understand and establish its role in Kenya more clearly.

BiodolomerOcean is made from natural materials and is more expensive to produce than traditional plastics. KMFRI has therefore been asked to identify possible economic models to finance the biodegradable nets and ropes.

The proposed model for seaweed farming is to introduce contract farming as part of the commercialization of the seaweed industry. Through contract farming, small-scale farmers will have access to cash for farming inputs (including biodegradable ropes). Contract farming will also make it possible for the farmers to expand and move farms to deeper, cooler water where the more profitable seaweed species strive. The model assumes that farmers may be paid more for seaweed that is sustainably farmed.

Gill nets cause an incredible amount of environmental damage. Used to capture large amounts of fish, they kill not only targeted species but any marine life that gets caught. Gill nets are also very likely to be lost at sea and are one of the most common causes of ghost fishing around the world.

On the other hand, gill nets are important for local economies as they underpin livelihoods, and contribute to food security for artisanal fishers and local communities involved in the fisheries value chain. An outright ban on the nets is therefore not an option. There is however a need to improve the understanding of the economic costs of plastic marine pollution and ghost fishing as this will assist in developing strategies for how to prevent, mitigate, and remediate the impacts of gill nets.

While noting that there has been a significant reduction in artisanal fisheries production in Kenya, the socio-economic study by KMFRI is looking at possible links between lost fishing gear and reduced fishing catches and how this translates into reduced incomes for local fisheries. It is also looking at how biodegradable nets can have a positive impact on the livelihoods of Kenyan artisanal fishers.

The socio-economic study is further exploring options for how to execute a national rollout of biodegradable gill nets. The switch to environmentally friendly fishing gear would most likely require the introduction of economic incentives. The project is looking for lessons learned from the Beach Seine Exit Project in Lamu Country. This was community-led conservation project that paid fishermen for handing in the extremely destructive seine net. The project had positive impacts not only on the local environment but noticeable impacts on the livelihoods of local fishermen.

Issue 10 - Nordic Bioplastic Conference

SHOWCASING THE LATEST INNOVATIONS IN BIOBASED AND BIODEGRADABLE PLASTICS

The Nordic Bioplastic Conference 2024 brought together experts from the entire bioplastics value chain to update the industry on developments within the field. The event featured industry case studies and market and application overviews with input from experts, policymakers, and consultants. GAIA Biomaterials had been invited to the Conference to present their last development in the R&D of Biodolomer®Ocean. GAIA Biomaterials, with its plant and head office in Helsingborg, Sweden manufactures biodegradable compounds that can be used with almost all traditional plastic production methods, from film blowing to 3D-printing. Its latest innovation Biodolomer®Ocean is a biodegradable biopolymer that aims to replace harmful plastics in the fishing industry.

Issue 9 - Biodegradation testing

Although there is strong science on the breakdown of PBS in nature, we are not working with a pure PBS and every additional copolymer or additive will have some effect on the rate and method of degradation. While we know that BiodolomerOcean can and will biodegrade, questions regarding its useful lifespan and rate of degradation are still to be answered precisely.

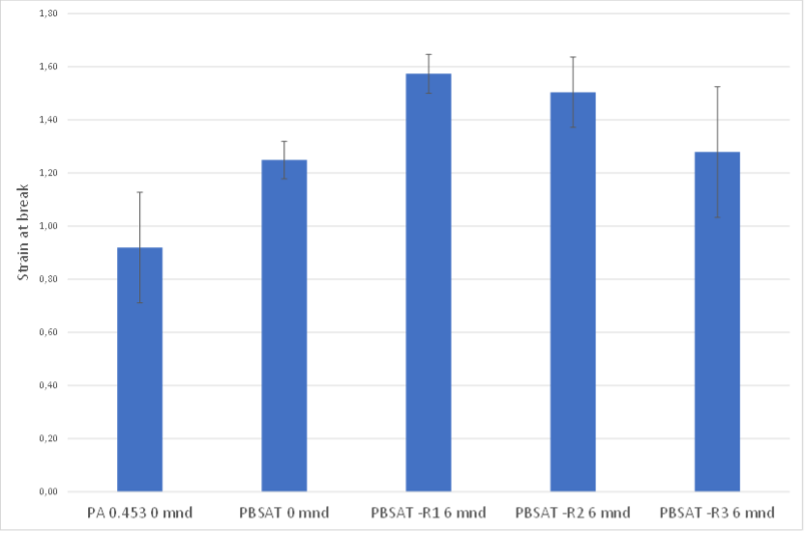

Four different grades are currently being tested for degradation and loss of tensile properties by SINTEF in Norway, using a variety of analytical tools.

Preliminary sampling of BiodolomerOcean after 6 months in marine sediment shows the material has not started the accelerated biodegradation process and that it remains intact both visibly, chemically, and mechanically.

These findings are good for the project as they imply that the material does not suffer a quick breakdown of the mechanical properties and that the material stands a chance to continue to perform in marine environments within the work-life needed by the industry.

The biodegradation testing at SINTEF will continue for another 24 months to monitor if microbes have started to assemble on the surface of the filament and have begun to compromise the material properties.

Plans are also in place to extend the laboratory tests to biodegradation testing after at-sea deployment of the material. This will provide us with direct proof of microbial bond breaking or de-polymerization in natural marine systems.

FTIR testing shows that there has been some loss of surface material and a small reduction in tensile strength. This primary degradation is likely a result of the removal of lower molecular species from the surface as predicted, potentially due to hydrolysis. This is indicated by a shift in the carbonyl peaks from 1715cm-1 to 1711cm-1 in some of our grades. The surface roughness has also increased slightly in at least two of the samples. This may be indicative of biodegradation, in line with previous research that has demonstrated slow biodegradation of a PBS-PBAT blend in cold seawater.

SEM analysis of the samples shows that the roughness of the surface area of the samples has not increased after 6 months. This also tells us that the material remains intact.

The result after tensile testing indicate that the mechanical properties of the samples remain the same and that the material does not suffer a quick breakdown of the machanical properties.

Issue 8 -Piloting results from Kenya

Biodegradable ropes in seaweed farming

Seaweed farming in Kenya is a growing industry with the potential to boost local economies, food security, and environmental health. However, the use of synthetic ropes in seaweed farming may be hazardous to the environment and a major source of microplastic pollution. In an attempt to mitigate potential environmental impacts, the Kenyan Marine and Fisheries Research Institute (KMFRI), in partnership with the Kubuyuni seaweed farmers, has piloted the use of biodegradable ropes for seaweed farming. The piloting, which started in August 2023, has been monitored over four growing cycles. Scientists compared the biomass production of the biodegradable ropes to the traditional synthetic ropes and also recorded the loss of seed and invasion of any foreign species.

The piloting of biodegradable ropes for seaweed farming demonstrated no significant difference in the loss of seeds or biomass produced compared to traditional synthetic ropes.

Biodegradable ropes in gill nets

Gill nets are the most commonly used nets by small-scale fisheries in Kenya, underpinning livelihoods and contributing to food security, Gill nets however are known for causing an unbelievable amount of damage and are also the net that is most likely to be lost at sea. Despite their frequent use, Kenya has prohibited the use of monofilament gill net. Together with the FAO, Kenya has also introduced a modified design of the gill net that replaces the synthetic twine that hangs up the multifilament net to the headline with twisted cotton. The design of the nets allows for the cotton to biodegrade and the nets to collapse should the nets be lost, thus preventing ghost fishing.

KMFRI, together with the Mikindani BMU, has replaced the headline and leadlines in these modified gill nets with biodegradable ropes and piloted for fishing efficiency. The fishing experiments were carried out for seven days in February 2024. Data on the type of fish, weight, and size of the fish was measured during the process.

The piloting of biodegradable gill nets demonstrated no significant difference in the type of species of fish caught, the size of fish caught, or the amount of fish caught compared to traditional synthetic nets.

The fishermen and farmers in the two pilots will continue to fish and farm, using the biodegradable ropes and nets until they are no longer functional, to measure the longevity of the biodegradable material. The ocean piloting of the biodegradable ropes is done parallel to laboratory biodegradability testing of the material by SINTEF, Norway, to measure the lifespan and rate of biodegradation.

Issue 7 - PBS-based BiodolomerOcean

PBS -based biodegradable material for marine applications

Catchgreen, in collaboration with GAIA Biomaterials, has developed the PBS-based biodegradable polymer Biodolomer®Ocean. This polymer is being trialed, as a spun rope, as a replacement for traditional HDPE fishing gear to reduce the negative impacts of ALDFG or “ghost fishing” by creating gear that will be metabolized into harmless biomass at its end-of-life.

Polybutylene succinate (PBS) has been shown to biodegrade into water and carbon in multiple environments, including compost and marine sludge sediments. This occurs in a two-step process whereby hydrolysis on the surface removes monomers and oligomers, which then metabolize in a reaction that is catalyzed by the naturally occurring enzyme PBSase.

Source Kim et.al. Polymer Degradation and Stability (2023)

Why PBS?

PBS has a balanced range of properties well-suited for marine applications.

PBS is marginally denser than conventional polymers, meaning that products (nets) derived from PBS will sink, removing their ghost-fishing potential and delivering them to microbe-rich ocean sediments.

PBS is a promising aliphatic polymer that can naturally biodegrade through digestion by microbes found in the ocean.

PBS can be produced from renewable monomer sources such as corn and sugarcane.

Biodegradation process of PBS

PBS (and other environmentally biodegradable plastics) are broken down by a two-phased process. Initially, mechanical wear (hydrolysis) causes lower molecules (monomers and oligomers) to be shed from the surface of the PBS. The inside of the material maintains its crystallinity and strength whilst the surface changes at a rate determined by environmental conditions including abrasion, temperature, and UV exposure. These lower molecular species shed from the surface are then broken down into CO2 and water by microorganisms and the enzyme PBSase. Soil, compost, and marine sediment all have higher concentrations of these microorganisms than seawater, meaning the bulk of the degradation process may be limited whilst a PBS-based polymer is in use, and accelerated when it reaches sediment.

Ocean testing

Previous research on PBS-based fishing gear has shown degradation after approximately 24 months and some loss in fishing efficiency after heavy use. Catchgreen is focused on overcoming these efficiency losses through selective replacement of net parts and application-tailored formulas.

Preliminary laboratory testing of Biodolomer®Ocean by SINTEF is promising and indicates early stages of degradation and small losses in tensile strength. Catchgreen is in the planning phase of the at-sea deployment of experimental seabed grates and nets to test the biodegradability of the nets in real-life conditions and different sea temperatures.

Issue 6 - Material Development

Catchgreen is celebrating the end of the year with yet another grade of Biodolomer®Ocean, to be tested in manufacturing trials at Alnet in January.

Biodegradable plastics for fishing gear

BY GAIA BIOMATERIALS (SWEDEN)

Catchgreen is working in partnership with GAIA Biomaterials, a leading biopolymer producer, in the development of a material that can replicate or exceed the performance of traditional plastic fishing gear, whilst being able to biodegrade or compost at the end of its usable lifespan – or when lost at sea. The benefits of such a material would be numerous, including the reduction of plastic pollution as macro-, meso- or microplastics, elimination of ”ghost nets”, and enhanced marine ecosystem and food supply resilience in line with global SDGs and the EU Mission: Restore our Oceans and Waters. This mission seeks to reduce plastic litter by 50% and microplastics by 30% by 2030 and has been a leading light for our project.

Key facts about Biodolomer®Ocean

Biodolomer®Ocean is a mix of PBS (polybutylene succinate) and PBAT (polybutylene adipate terephthalate)

Biodolomer®Ocean is manufactured in recognisable orange and turquoise to distinguish it from traditional fishing gear.

Biodolomer®Ocean is designed for mono-extrusion and the spinning of thread.

Biodolomer®Ocean will be used to manufacture various types of ropes and nets for fishing and aquaculture industries.

Biodolomer®Ocean

MATERIAL DEVELOPMENT

Working together with Catchgreen, R&D Manager Konrad Rosen and his team at GAIA have developed an alternative to the polyamide HDPE that is used in conventional polluting plastics in the manufacturing of fishing gear due to their useful properties – high strength, flexibility, resilience, and toughness. Our alternative, better material will need to emulate these properties, be manufactured and processed in a similar way in existing machines, perform in harsh environments for up to three years, and biodegrade in the ocean if lost or in compost if recovered at end-of-life.

GAIA has been working on a recipe that allows for durability during use yet degradation if lost at sea or during the end-of-life phase – a juggling act of the highest degree. Building on the proven success of biodegradable Biodolomer but optimizing for this application was never going to be easy, and required a rethink of the binder better suited for purpose. PBS was selected as the binder and was copolymerized with PBAT (polybutylene adipate terephthalate), another biodegradable polymer similar to fossil-based polyethylene with good flexibility and resilience.

Why PBS?

Polybutylene succinate (PBS) is a promising aliphatic polymer that can naturally biodegrade through various routes, including digestion by microbes found in the ocean. This polymer has a balanced range of properties well-suited to this application, notably thermal stability, flexibility, and ductility, as well as good processability across a wide range of temperatures.

A final grade for scale-up in 2024 is ever nearer, and although we are overjoyed with the great strides GAIA has made in bringing us the results we have we are, as always, looking forward and improving. Further development is planned before production scales, mainly focused on increasing toughness, stress, and flaw sensitivity by adding a polymeric chain extender to react with the chain ends of the PBS and increase the melt viscosity of the material.

Issue 5: INC-3 Plastic Treaty Negotiations

Catchgreen attended the Third Session of the INC-# Plastic Treaty Negotiations.

INC-3 Plastic Treaty Negotiations

RETHINKING THE FUTURE OF SINGLE-USE PLASTIC

Catchgreen attended the Third Session of the INC Plastic Treaty Negotiations in Nairobi and was invited by SMEP project partners UNCTAD to speak at a pre-event on “Trade and development aspects of plastic pollution mitigation measures, non-plastic substitutes, and plastic alternatives”. Catchgreen was able to present updates from the piloting of the biodegradable ropes for seaweed farming and preliminary findings on the added benefits of increased growth in warmer sea temperatures. Catchgreen, together with piloting partner KMFRI, had the opportunity to display the biodegradable nets and ropes, emphasising the importance of allowing for innovation and new product development within the framework of the plastic treaty.

Plastic Alternative Working Group

The PlasticTreaty should recognise the need for plastic alternatives and allow for innovation.

It is essential to differentiate between different plastic alternatives, to communicate their different benefits, and to label them properly to ensure they are used for the right applications and end up in the right waste management stream,

There is a need to harmonise certification and demand testing, to ensure zero microplastics and toxins leaking into the environment.

Each new application in alternative plastics should be tested in the environment where it will be used.

Preferred applications in plastic alternatives include agriculture, fisheries, and problem plastics that cannot be recycled.

The lack of information and unfortunate greenwashing foster skepticism and lobbying against plastic alternatives.

PROBLUE

LOST AT SEA

Catchgreen participated in the World Bank PROBLUE pre-event “Lost at Sea: Combating Abandoned, Lost, and otherwise Discarded Fishing Gear”. Building on the momentum from INC-2 to inform the zero draft on the life cycle of fishing gear, the event showcased new work from key partners and facilitated a great discussion on actions needed from production to use to the end-of-life stages of fishing gear. Glen Wilson from UNCTAD shared updates on Catchgreen’s piloting of biodegradable fishing gear by piloting partners KMFRI. Dr. Susan Imende from the Kenyan State Department for Fisheries, Aquaculture, and the Blue Economy shared a perspective on the use of biodegradable nets and ropes as a solution to ALDFG in Kenya.

Fishing gear ropes and twine for aquaculture account for up to 27% of African marine litter. These become “ghost nets” when accidentally lost, abandoned, or discarded in the marine environment, continuing to catch both target and non-target species; entangling and killing marine animals, imposing danger to boat operations, damaging coral reefs and seabed and presenting a safety hazard for ocean users.

Biodegradable fishing gear can reduce the incidents and duration of “ghost fishing”. If lost or dumped, the biodegradable fishing gear, due to the high density of the biodegradable material, will sink to the bottom of the sea, where the richness of microorganisms on the ocean floor speeds up the biodegradation process. The end-product of this biodegradation process is biomass that contains no traceable toxins or microplastics.

ALDFG in Africa

The impacts of ALDFG are particularly concerning on the African continent, given that more than 200 million people in Africa rely on fish for high- quality low-cost protein and approximately 12 million people are employed in the fishing sector.

The impacts of ALDFG pose a serious threat to food security, long-term economic growth, the viability of marine ecosystems, and the development of a vibrant and productive blue economy.

Old and discarded fishing nets contribute to the stockpiling of plastics in landfills where they take up to 1000 years to decompose, leaching potentially toxic substances into the soil and water.

Issue 4 - Piloting Ropes for Coral Restoration

Catchgreen visited Wasini Island and the piloting of biodegradable ropes in their effort to retire the communal coral reefs. It was only two weeks since the ropes with coral fragments had been placed on the damaged reefs and already you could see the small corals growing on the ropes.

Coral reef restoration

WASINI ISLAND, KENYA

With financial support from SMEP and the ICDO, the Catchgreen project has developed an innovative compound, Biodolomer®Ocean, designed specifically for marine applications. The Kenyan Marine and Fisheries Research Institute (KMFRI) and the Wasini Beach Management Unit (BMU) recently started pilots with ropes in Biodolomer®Ocean for coral restoration. The piloted method offers cost-effective and accelerated coral restoration and a sustainable solution to bringing back marine life to the overfished and damaged reefs. By restoring the coral reefs, the local fishermen have noticed an increase in available fish which brings in important income to the community. The Wasini BMU also get an income from tourist who visit the community-protected area. Divers are invited to plant corals and learn about the importance of coral restoration.

Biodegradable ropes for coral restoration

ACCELERATED CORAL RESTORATION

Ropes can play a vital role in coral restoration efforts as they are used to create structures that can support and protect newly planted coral fragments. These structures, known as "coral nurseries," provide a safe environment for corals to grow and mature, allowing them to eventually be transplanted onto damaged reefs. To create a coral nursery, ropes are strung between anchors, creating a grid-like structure. Coral fragments are then attached to the ropes which allows them to grow without being dislodged by waves or currents. As the coral grows and matures, the corals form a natural structure that provides a habitat for other marine life.

To minimize the environmental damage caused by ropes in coral restoration, ropes in Biodolomer@Ocean will be piloted to secure coral fragments, and because they break down naturally over time they will also be used to secure the grown coral fragments onto the reefs. The ropes in Biodolomer®Ocean, at the end of their lifetimes, will break down into biomass, water, and carbon dioxides. The KMFRI-supported project will monitor the growth and survival rates of the planted corals and the return of biodiversity for one year.

Issue 3 - Piloting Ropes for Seaweed Farming

The piloting of biodegradable ropes for seaweed farming started in August 2023 and will continue for one year. The first monitoring of the ropes took place two weeks after planting and showed that the seaweed had taken to the biodegradable ropes and grown to a similar size as to those that were planted on the normal plastic ropes.

Biodegradable ropes for seaweed farming

KMFRI, KIBUYUNI (KENYA)

Seaweed farming is a sustainable and environmentally friendly industry that has gained popularity in recent years. The expansion of seaweed farms has the potential to boost local incomes, food security, and environmental health. However, the plastic ropes that are used in seaweed farming can have devastating impacts on the marine environment. To mitigate these impacts, Catchgreen, in partnership with the Kenyan Marine and Fisheries Research Institute (KMFRI) and the Kibuyuni seaweed farmers, is piloting Biodolomer®Ocean ropes. These biodegradable ropes are designed to reduce toxic plastic accumulation in the ocean. It takes approximately 2 years for Biodolomer®Ocean to break down into biomass, water, and carbon dioxides.

Women-led seaweed farming

FOR HUMANS AND ECOSYSTEMS

Seaweed farming in Kibuyuni village presents an opportunity for women’s participation in the Blue Economy. It enables women to improve their livelihoods while it also benefits the environment. Mama Fatma is a pioneer seaweed farmer and tells the story of how, thanks to seaweed, the women have sent their children to school, renovated their homes, and how it has contributed to the health of local ecosystems. “The ocean is our life. By planting seaweed, we help to clean up the ocean. The seaweed attracts fish. It brings us food on the table and sends our children to school, we even have electricity here now.” With the support of KMFRI scientists, the women have been taught how to plant, harvest, and process seaweed for the export market. Some of your village youths have been encouraged to add value to the seaweed by making various cosmetic products.

The women in Kibuyuni village are now participating in the piloting of the Biodolomer®Ocean ropes. The women have planted seaweed with the biodegradable ropes side by side with normal plastic ropes and will take bi-weekly measurements to compare the growth rate and dry biomass of the two ropes. The ropes will be tested regularly for strength and biodegradability. Once the biodegradable ropes start breaking, they will be subjected to composition under normal decomposition conditions to simulate the decomposition of recovered ropes. Bringing seaweed farming and scientific research to the village is capacitating women to take ownership of the marine environment on which they depend for their livelihoods.

Issue 2-Piloting Gillnets

Catchgreen is working with KMFRI to modify the commonly used gillnets by adding Biodolomer®Ocean biodegradable head and lead lines. The nets will be piloted over a period of a year to confirm the functionality and durability of the nets.

Real-life ocean pilots

KMFRI, MOMBASA

The Catchgreen project has partnered with the Kenyan Marine and Fisheries Institute (KMFRI) to pilot Biodolomer®Ocean twine for modified gill nets. The inception meeting for these pilots occurred in Mombasa, Kenya where fishermen from the Mikindani Beach Management Unit (BMU) demonstrated how they had modified gill nets to replace the headlines and leadlines with the biodegradable twine. The modified gill nets are designed to prevent ghost fishing and reduce toxic plastic accumulation in the marine environment. Biodolomer®Ocean, if lost or at its end of use will break down into biomass, water, and carbon dioxides. The real-life ocean pilots will confirm the fishing efficiency of the modified nets.

Gill net modification

A BALANCE BETWEEN STRENGTH AND EFFICIENCY

The pilot of the modified gill nets is a continuation of an FAO-funded project that replaced the synthetic twine used to hang multifilament net to the headline with twisted cotton. The modified design of the nets allows for the cotton to break down and the nets to collapse should the nets be lost, thus preventing ghost fishing. The nets can then be retrieved through a buoy and float system. By adding Biodolomer®Ocean twine to the design, the impact of the nest, should they be lost, is significantly reduced. The pilots include composting trials of old and discharged nets in Biodolomer®Ocean to reduce the amount of plastics accumulating on land and in the ocean.

The impacts of abandoned, lost, or otherwise discarded fishing gear (ALDFG) are particularly concerning in Africa, where more than 200 million people rely on fish for high-quality low-cost protein and approximately 12 million people are employed in the fishing sector. The impacts of ALDFG pose a serious threat to food security, long-term economic growth, the viability of marine ecosystems, and the development of a vibrant and productive blue economy. Using biodegradable materials to manufacture fishing gear can provide a viable solution to tackling ocean plastic pollution, by providing substitution material from which to make fishing-related equipment such as the modified gill nets.

Issue 1 - Manufacturing Trials

The first issue of the Catchgreen Newsletter is out. Read about the successful manufacturing trials of Biodolomer®Ocean that took place at Alnet, South Africa.

Manufacturing trials

ALNET, CAPE TOWN

Against the backdrop of green and sustainable solutions in the blue economy, Catchgreen, a cross-sector collaborative research project that aims to address ghost fishing by innovating a biodegradable alternative, conducted its first manufacturing trials between the 26th and 29th of June. The manufacturing trials took place at Alnet, Cape Town, and were conducted together with partners GAIA, FishSA, and Kompost-It. Present at these trials were also representatives from research & piloting organizations KMFRI, I&J, Steenberg, Coastal Cape Kelp, Green House, and our funders from SMEP.

The manufacturing process

A BALANCE BETWEEN STRENGTH AND FLEXIBILITY

The core objective of the manufacturing trial was to understand the process of the developed biopolymer, particularly its behavior under varied settings (temperature, pressure, processing speed) as well as its functionality. Achieving optimal behavioral limits of the material at its first manufacturing phase meant stretching the boundaries of the measured parameters for practical understanding and improvement of future manufacturing and processing. A certain level of messiness (technical glitches, material wastage) in doing this was thus an inevitable outcome as experienced on the first day of the trial.

The second day was more successful with adjusted settings, which made it possible to produce ropes for specific applications in the first set of planned piloting. Piloting will be conducted in the next six months to test the following applications: modified gillnets, seaweed farming, coral reef restoration, kelp farming; and lobster cages.

Overall, this first process was a success and all partners agreed it was indeed an impressive first manufacturing trial. They were also pleased to be part of a project that makes a difference in the green transformation discourse in the blue economy.